- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

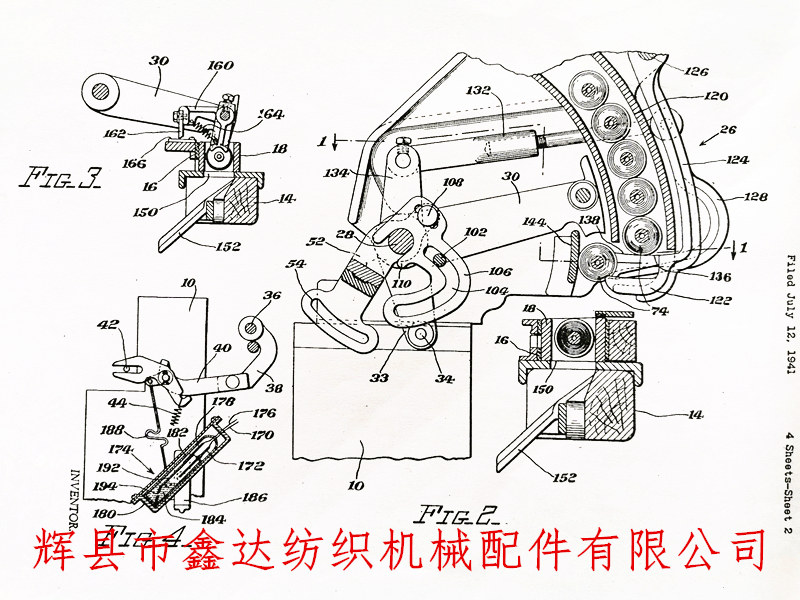

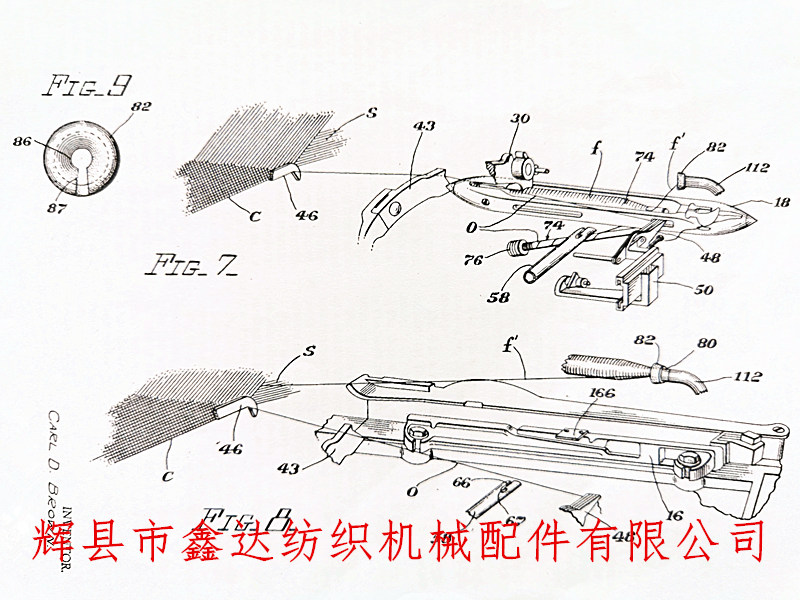

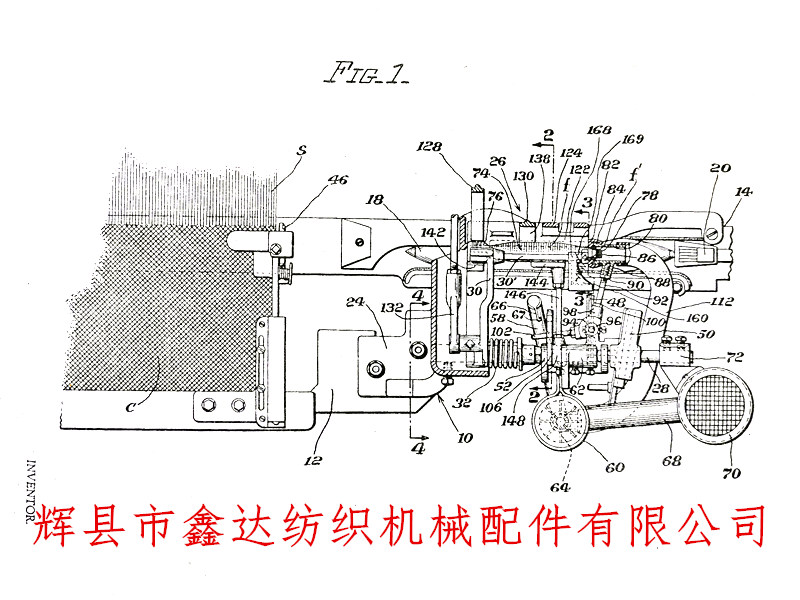

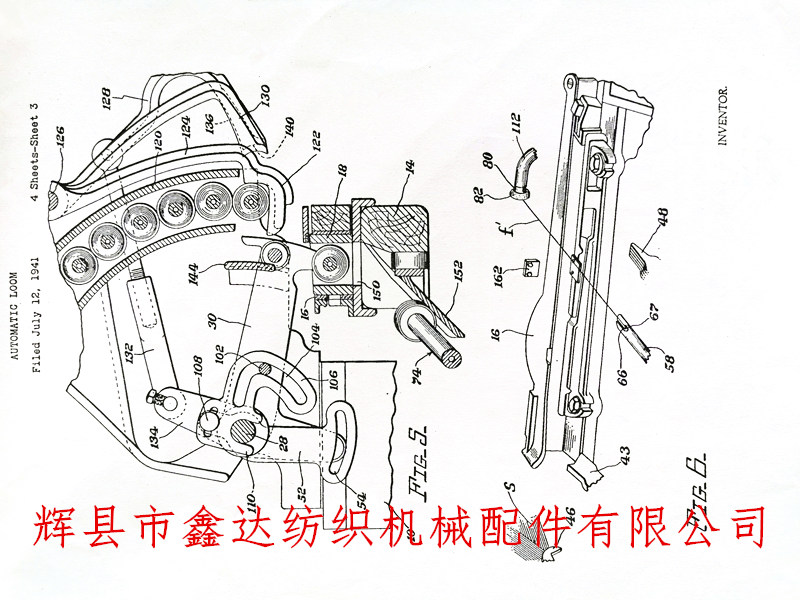

Description And Aufbau Principle Of G263 Series Disc Loom

This article focuses on the description and Aufbau principle of G263 series disc Loom. We use drawings such as the principle of bobbin changing and picking to give a detailed and comprehensive introduction to the automatic bobbin changing structure, so that the textile industry can be fully familiar with the description of Loom, the principle of Loom, the parameters of Loom, and the principle of disc looms, and meet the requirements of improving the innovative production and maintenance technology of Loom and updating the equipment of Loom in China.

Introduction:

G263 (Z) disc loom is a cotton loom suitable for weaving pure cotton and blended cotton yarn. It is suitable for weaving fabrics with a weft density of 40-80 pieces/inch. There are mainly three types of loom door widths: G263-1250mm, G263Z-1350mm, and G263Z-1500mm. The machine speed is 185-200r/min, and the warp disc adopts φ 550mm or φ 600mm, equipped with the same motor as the 1511 and 1515 models -0.8KW.

(1) Shuttle size: 390mmX48mm X35mm (total shuttle length X shuttle bottom width X shuttle wall height)

(2) Size of weft tube with iron hoop: 190mm long, outer diameter of weft tube hoop 27mm

(3) Reed size: 1302mm long X 120mm high, 1404mmX120mm, 1578mm X120mm (calculated according to the door width of the Loom).

When the G263 disc Loom works normally, it operates smoothly, the three spindles rotate flexibly, the axial clearance is less than 0.4mm, the crankshaft gear and the pedal shaft gear are well matched, and the tooth side clearance is less than 1.5mm. When the clutch starts working, the fully opened shuttle opening should be clear, and there should be no abnormal clamping phenomenon when the shuttle enters and exits the shuttle track.

(1) The reed seat of the disc loom is located at the lower warp surface of the rear center shed, which is about 1mm away from the plane of the shuttle board or flat, and cannot cause friction with the shuttle board. When the reed seat is in the rear center, a gap of 15-20mm should be maintained between the front heald frame and the reed cap.

(2) The surface of the tread plate has good contact with the surface of the tread rotor, and the parallelism of the contact surface is 0.2mm.

(3) The surface contact between the shuttle rotor and the shuttle nose is good, with a parallelism of 0.1mm on the contact surface. The angle between the shuttle box bottom plate, the shuttle box back plate, and the shuttle box front plate is 86.5 °.

(4) Shuttle box width: the inner side is the width of the shuttle+3mm, and the outer side is the width of the shuttle+1.6mm; Shuttle box height: The inner side is the shuttle height+4mm, and the outer side is the shuttle height+2mm.

(5) The shuttle surface at the junction of the shuttle box bottom plate and the shuttle board must be flush, with a horizontal shuttle board arc (concave) of 1.5mm and a steel reed (convex) of 1.5mm.

(6) The relative displacement of the coiling hook is three teeth and a half, the gap between the side support box and the steel reed is 1.6mm, and the distance between the side support cover edge and the shuttle plate surface is 22mm (G263) and 32mm (G263Z).

Technical requirements for fiber exchange system:

(1) The ratchet sleeve rotates flexibly, and the three pawls have good contact with the ratchet. When the handle is pulled and released again, the ratchet can rotate one tooth on its own.

(2) The positions of the disc, keyboard, and yarn guide are aligned with each other, and the guide iron plane is flush with or retracted by 0.5mm from the concave surface of the disc

(3) The gap between the curved surface of the replacement hammer and the pipe clamp: 3mm when lifting up and 1mm when pressing down.

The above is the description of the G263 Loom and the principle of the G263Z Loom. The attached picture is the Aufbau principle diagram of the disc Loom. The different design methods of the disc Loom are complementary to the types of fabric changing and shuttle changing looms, which are based on reducing the failure rate and improving the production efficiency.